High definition Mold Injection - China custom molding injection mould design water cup plastic bottle cap mold – Plastic Metal

High definition Mold Injection - China custom molding injection mould design water cup plastic bottle cap mold – Plastic Metal Detail:

2021 Yuyao Cixi Ningbo Zhejiang auto parts stamping die/mould/mold/bulb lights and Plastic injection molding

Item: ningbo Mold/Plastic Mould /auto parts stamping die/mould/molding /Injection plastic mold/Plastic injection molding/ Plastic Injection Mould /mould maker/printer mould/ Plastic toolings maker Specifications.

1. About our company

1) We have been doing professional bulb lights and bulb lightsing products for 14 years, equipped with 30 sets mold processing equipment, proffessional CAD, CAM, CAE technology and special testing equipment.

2) 2012 three-star mold Factory.

3) Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc…

4) We will Quote you our best price on time, please provide detailed information when send inquiry.

5) please inform the molding material, weight, annual purchase quantity, target completion time and other special requirements (eg: UV, VO, painting, chrome, screen printing, assembly and so on).

2.Discription of bulb lights

| Item | Custom Plastic Mold |

| Mould Time | 20-35 Days |

| Product time | 7-15 Days |

| Moud precision | +/-0.01mm |

| Mould life | 50-100 million shots |

| Mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Mould cavity | One cavity, multi-cavity or same different products be made together |

| Runner system | Hot runner , Cold runner |

| Surface treatment | Words corrosion,Mirror polish,Frosted surface,Dermatoglyph |

| Mould standard | HASCO,DME or according to custom’s request |

| Main process | Milling,grinding,CNC,EDM,wire-electrode cutting, carved,electrospark,lathe,surface treatment |

3.Plastic Injection Mould making

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample’s inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

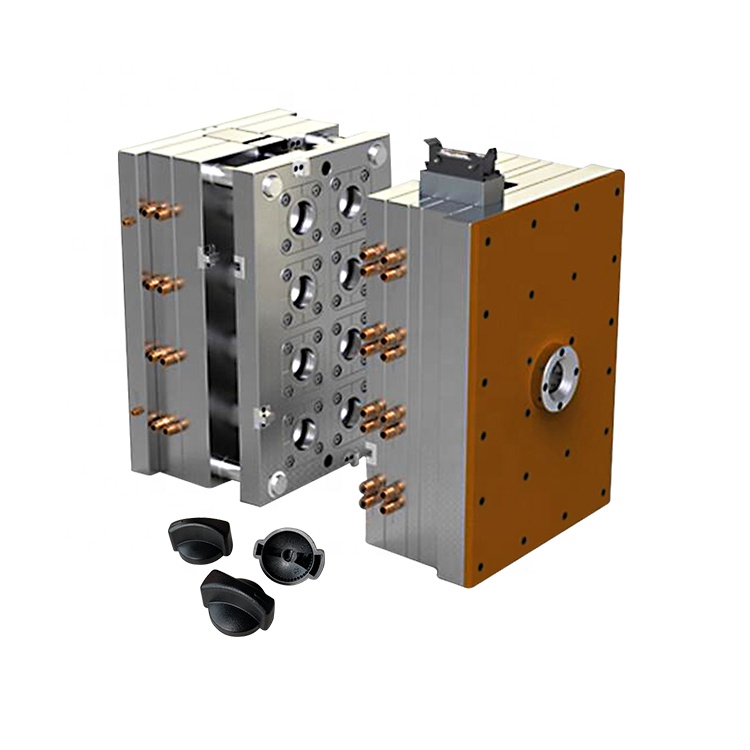

4.Pictures

Why choose us ?

1.We are a professional factory with more than 14 years’ experience

2.Accept OEM design: can produce any design as your requirement

3.We have a professional design team to make the sample meet your satisfaction.

4.Quick production,high quality silicone materials as customers require

5. Strict quality control before shipment

6.We specially focus on after-sale service

5. Our Exhibition, Partner and Certificate

Product detail pictures:

Related Product Guide:

Cooperation

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for High definition Mold Injection - China custom molding injection mould design water cup plastic bottle cap mold – Plastic Metal, The product will supply to all over the world, such as: Senegal, Kenya, Brazil, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.