You play a vital role in advancing automotive sustainability by choosing EU-compliant materials. Custom Parts Out of Plastic align with 2025 standards by ensuring recyclability, lightweight designs, and reduced emissions. These parts help you comply with strict regulations, lower production costs, and contribute to a greener future for the automotive industry.

Key Takeaways

- Custom plastic parts that follow EU rules help companies avoid fines.

- Lightweight plastic parts make cars use less fuel and pollute less.

- Using recycled materials cuts waste, supports reuse, and boosts eco-friendly image.

2025 EU Automotive Sustainability Standards

Key Requirements for Automotive Manufacturers

The 2025 EU automotive sustainability standards set clear expectations for manufacturers. You must prioritize reducing environmental impact while maintaining product quality. These standards focus on three main areas: material compliance, recyclability, and carbon emissions. Meeting these requirements ensures your vehicles align with the EU’s vision for a greener future.

Tip: Start by evaluating your supply chain. Ensure all materials meet EU regulations and support sustainability goals.

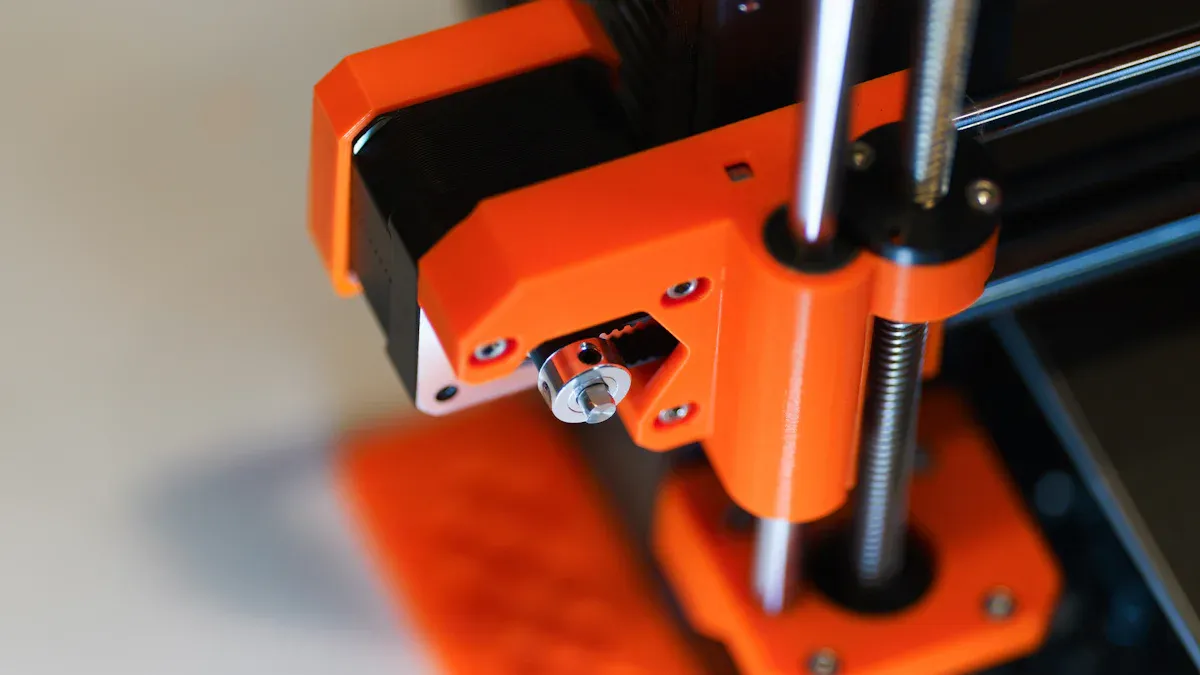

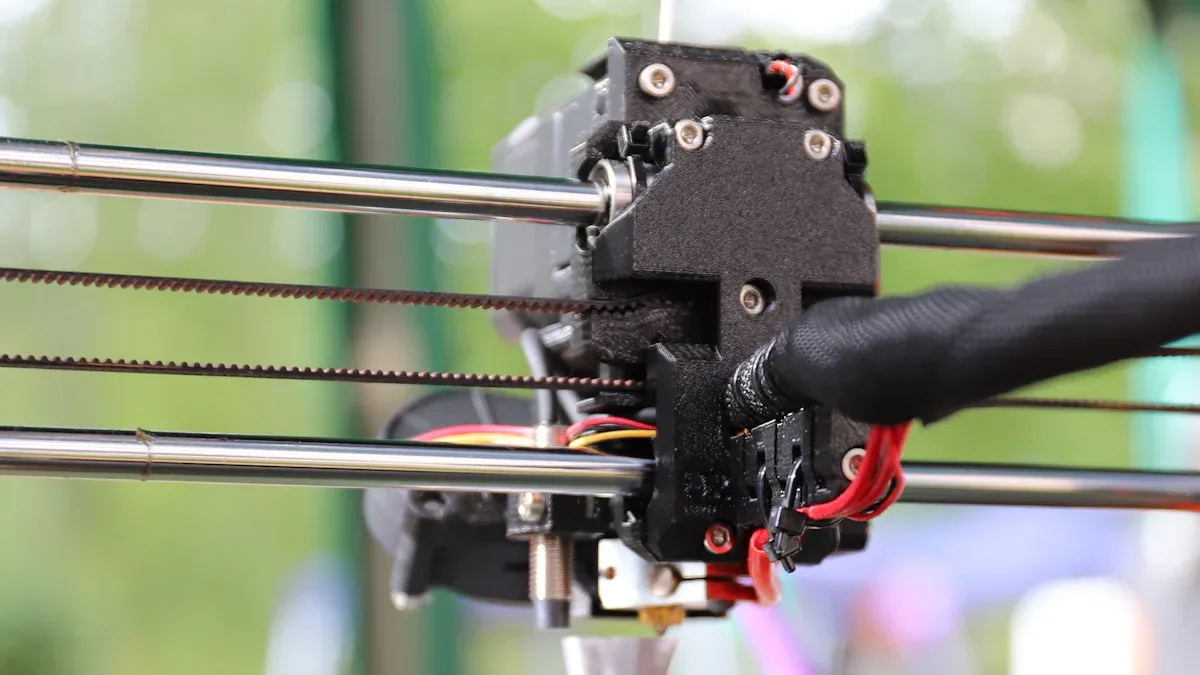

You also need to adopt innovative manufacturing practices. Using lightweight materials, such as Custom Parts Out of Plastic, can help you achieve compliance. These parts reduce vehicle weight, improving fuel efficiency and lowering emissions. By addressing these key areas, you can stay ahead of regulatory changes.

Focus on Recycled Content and Circularity

Recycled content plays a vital role in meeting sustainability goals. You should integrate recycled materials into your designs to reduce waste and conserve resources. Circularity, or the reuse of materials, is another critical focus. This approach minimizes landfill waste and promotes a closed-loop system.

For example, using Custom Parts Out of Plastic designed for recyclability supports circularity. These parts can be reused or repurposed, reducing the need for virgin materials. By embracing recycled content and circularity, you contribute to a more sustainable automotive industry.

Stricter CO₂ Emission Standards for Vehicles

The EU has introduced stricter CO₂ emission standards for 2025. These regulations require you to lower emissions across your vehicle lineup. Lightweight materials, such as plastic components, play a key role in achieving this. They reduce the overall weight of vehicles, improving fuel efficiency and cutting emissions.

Note: Non-compliance with these standards can result in significant penalties. Prioritize emission reduction strategies to avoid fines and maintain market competitiveness.

By focusing on these areas, you can meet the EU’s ambitious sustainability targets while enhancing your brand’s reputation.

Custom Parts Out of Plastic and Their Role in Sustainability

Material Compliance with EU Regulations

You must ensure that every material used in your vehicles meets EU regulations. Custom Parts Out of Plastic help you achieve this by adhering to strict guidelines on chemical composition and safety. These parts often use materials free from hazardous substances, such as lead or mercury, which ensures compliance with the EU’s REACH and RoHS directives. By choosing compliant materials, you avoid penalties and maintain trust with regulators and consumers.

Tip: Work closely with suppliers to verify that all plastic components meet EU standards. This proactive approach saves time and prevents costly redesigns.

Design for Recyclability and Lightweighting

Custom Parts Out of Plastic are designed with recyclability in mind. Their composition allows for easy disassembly and reprocessing, which supports waste reduction. Lightweighting is another key benefit. These parts reduce the overall weight of vehicles, improving fuel efficiency and lowering emissions. For example, replacing metal components with plastic alternatives can significantly cut vehicle weight without compromising strength or durability.

Note: Lightweight designs not only reduce emissions but also enhance vehicle performance, offering a win-win for sustainability and functionality.

Contribution to Circular Economy Goals

You can contribute to the circular economy by integrating Custom Parts Out of Plastic into your designs. These parts are often made from recycled materials and can be reused at the end of their lifecycle. This approach minimizes waste and reduces the demand for virgin resources. By adopting circular practices, you align with EU sustainability goals and demonstrate your commitment to environmental responsibility.

Call to Action: Start incorporating recyclable and reusable plastic parts into your production process today. This step positions your brand as a leader in sustainable innovation.

Benefits of EU-Compliant Custom Plastic Parts

Regulatory Compliance and Avoiding Penalties

Meeting EU regulations is essential for your business. Non-compliance can lead to hefty fines and damage your reputation. EU-compliant custom plastic parts ensure that your materials meet strict guidelines, such as the REACH and RoHS directives. These parts are free from hazardous substances, making them safe and environmentally friendly. By using compliant materials, you avoid penalties and maintain trust with regulators and customers.

Tip: Regularly audit your supply chain to confirm that all components meet EU standards. This proactive step can save you time and money.

Cost-Effectiveness and Sustainable Manufacturing

Custom plastic parts offer a cost-effective solution for your manufacturing needs. Their lightweight nature reduces material costs and improves fuel efficiency in vehicles. This efficiency translates to lower production and operational expenses. Additionally, these parts support sustainable manufacturing by incorporating recycled materials. Using recycled content reduces the need for virgin resources, cutting costs while promoting environmental responsibility.

Note: Investing in sustainable materials today can lead to significant savings in the long run.

Enhancing Brand Reputation and Market Competitiveness

Sustainability is a key factor for consumers when choosing a brand. By integrating EU-compliant custom plastic parts into your designs, you demonstrate a commitment to environmental responsibility. This commitment enhances your brand’s reputation and sets you apart from competitors. Customers value companies that prioritize sustainability, which can lead to increased loyalty and market share.

Call to Action: Highlight your use of sustainable materials in your marketing efforts. This transparency can attract eco-conscious consumers and boost your brand image.

EU-compliant custom plastic parts play a vital role in achieving the 2025 automotive sustainability standards.

- They help you meet regulations, reduce costs, and improve environmental impact.

- These parts also enhance your brand’s competitiveness by showcasing sustainability.

Tip: Start adopting these materials today to lead the way toward a circular automotive future.

FAQ

What are EU-compliant custom plastic parts?

EU-compliant custom plastic parts meet strict European Union regulations. These parts adhere to standards for material safety, recyclability, and reduced environmental impact, ensuring compliance with sustainability goals.

Tip: Always verify your suppliers provide certified EU-compliant materials.

How do custom plastic parts support lightweighting?

Custom plastic parts replace heavier materials like metal. This reduces vehicle weight, improves fuel efficiency, and lowers CO₂ emissions, helping you meet the EU’s 2025 sustainability standards.

Why is recyclability important for automotive parts?

Recyclability reduces waste and conserves resources. It supports the circular economy by enabling materials to be reused, aligning your production with EU sustainability goals and reducing environmental impact.

Note: Designing for recyclability also minimizes landfill contributions.

Post time: Apr-11-2025